- All products are added to your cart.

Key systems

Choosing a lockout tagout key system

1. Determine the number of employees that you require on this lockout-tagout system.

2. Determine how many employees will need to receive more than one safety padlock for lock-out. Those employees should get KA (Keyed Alike) padlocks.

3. Choose one of the following Safety Keying Systems:

- Keyed different (KD) *

- Keyed alike (KA) *

- Master keyed (MK) *

- Grand master keyed (GMK)

- Keyed alike master keyed (KAMK) *

* Available through the webshop

Types of key systems

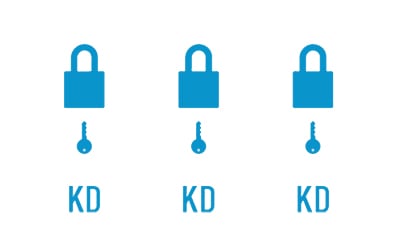

KD | Keyed Different

The key opens only one padlock.

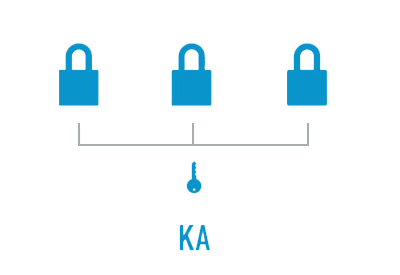

KA | Keyed alike

Each padlock has its own key. All keys are the same and open all padlocks within in a group.

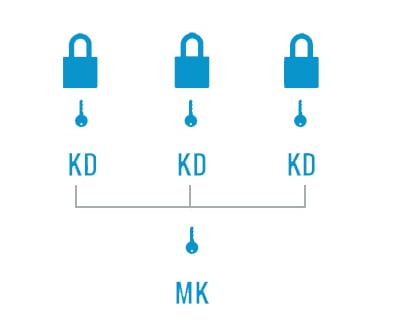

MK | Master keyed

A Master Key can open all padlocks across several groups (KD and or KA).

Key charting

To maintain the integrity of a Safety Lock-Out System, it is vital to ensure no duplicate keys are issued. Lockout-tagout-shop provides a Free Key Charting Service to record the key numbers used by customers. Once a system is registered, Lockout-tagout-shop.com will send you a unique USER I.D. number. By using that I.D. each time you order padlocks, we assign a new key code for each new lock. Thus ensuring no unintended duplication of keys.

Engraving

A permanent and durable method to customize your safety lock-out padlocks.

Available on: Padlocks from Abus, Brady and Masterlock

Areas for engraving:

Front, back, both sides of the padlock body and the key. De engraving may include, text, numbers and symbols. For the engraving of logos we need a -.pcx, -.tif or .bmp format files.

For orders with unique engravings on every padlock we provide an Excel®-spreadsheet. Please beware to not exceed the maximum length of the engraving.

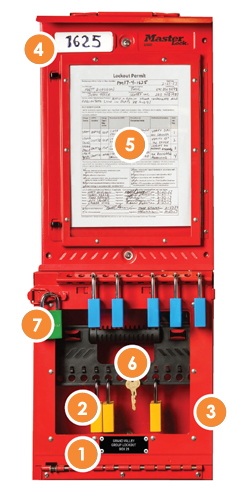

Setting up a group lockout system

Properly setting up your permit station can further improve the effectiveness of group lockout execution:

- During the energy-isolation process, workers can use documentation, key number and the balance of locks in the box to verify the lockout was performed correctly.

- During equipment audits, missing locks are easy to identify. Engraving the key number on the locks will simplify the process of ordering replacements.

|

Setting up your station |