- All products are added to your cart.

Lockout Tagout (LOTO) Procedures

Lockout-Tagout (LOTO) Procedures: Complete Guide, Steps, and Compliance Requirements

A Lockout-Tagout procedure is the standard method for safely isolating hazardous energy before maintenance, servicing, or inspection is performed on industrial machinery. Every year, thousands of workplace accidents occur because machines are not fully de-energized. A correct LOTO procedure prevents unexpected startup, residual energy release, and serious injuries.

This guide provides a step-by-step LOTO procedure, an overview of relevant OSHA and European regulations, and practical considerations for safe energy isolation.

What Is a Lockout-Tagout Procedure?

A LOTO procedure (or LOTOTO when the “Try-Out” step is included) is a documented process that describes how a machine is shut down, isolated, locked, and verified before work begins. The objective is always the same: identify, isolate, lock, tag, and verify all energy sources.

An effective LOTO procedure includes:

- identification of all hazardous energy sources

- a clear shutdown and isolation sequence

- application of lockout devices and personal padlocks

- verification that all energy has been removed

- tagging and documentation

- a controlled release of equipment after work is completed

OSHA 1910.147 – International Reference for Lockout-Tagout

Many global companies use OSHA Standard 1910.147 as the foundation for their Lockout-Tagout programs. This standard outlines the minimum requirements for controlling hazardous energy and defines the performance specifications for lockout devices.

Key OSHA requirements include:

- Identifiable: Lockout devices must be clearly recognizable.

- Exclusive use: Devices must only be used for energy control.

- Durable and reliable: Resistant to corrosion, chemicals, and industrial use.

- Standardized: Consistent color, shape, or size within the facility.

Products supplied by Lockout-Tagout-Shop.com meet OSHA requirements and are designed for demanding industrial environments.

European Regulations for Energy Isolation

European directives, including provisions from the Work Equipment Directive, require employers to ensure safe isolation of hazardous energy during maintenance. Employers must:

- take all necessary measures to minimize risks to workers,

- apply and regularly review safety procedures,

- clearly label equipment that has been isolated,

- ensure that all energy sources are locked and verified before maintenance begins.

This makes a documented LOTO procedure a legal requirement whenever hazardous energy is present.

Which Risks Are Controlled by a LOTO Procedure?

Lockout-Tagout prevents injuries caused by uncontrolled or unexpected energy release. Typical energy sources include:

- electrical energy

- hydraulic pressure

- compressed air

- gas

- steam

- fluids such as water, oil, or chemicals

A proper LOTO program ensures that all forms of energy are fully isolated and verified before work begins.

Step-by-Step Lockout-Tagout Procedure

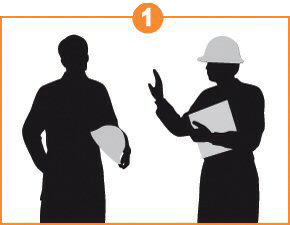

1. Coordination and Preparation

Discuss the task with the maintenance team, identify all energy sources, confirm the scope of work, and determine how long the equipment will remain locked out.

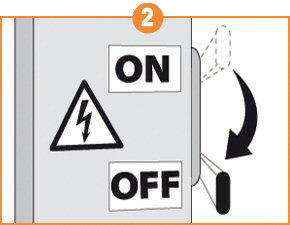

2. Machine Shutdown and Energy Separation

Shut down the machine following approved procedures. A simple emergency stop is not sufficient. Physically isolate all energy sources and release any stored or residual energy.

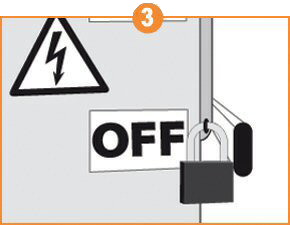

3. Application of Lockout Devices

Apply lockout devices to isolation points and secure each device with a personal safety padlock. Only the person who applied the lock may remove it.

4. Verification (Try-Out)

Verify that all energy has been successfully removed. This can include a controlled start attempt, visual inspection, or measurements to confirm zero energy.

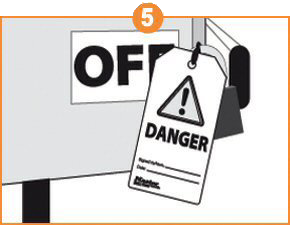

5. Tagging and Communication

Attach tagout labels to indicate that the equipment is locked out and must not be operated. Clear communication prevents unauthorized restart.

6. Mechanical Immobilization

Block or secure any moving components to prevent unintended movement during maintenance.

7. Marking and Securing the Work Area

Clearly mark the work zone and restrict access to hazardous areas to protect personnel from falls, moving equipment, or accidental entry.

Lockout-Tagout Equipment for Safe Energy Isolation

Lockout-Tagout-Shop.com supplies high-quality lockout devices designed for industrial use. Our products are resistant to extreme temperatures, chemicals, corrosion, and UV exposure. Common LOTO equipment includes:

- personal safety padlocks

- lockout hasps and group lockout solutions

- valve lockouts for gate valves, ball valves, and pneumatic valves

- electrical lockouts for breakers and disconnect switches

- tagout labels and identification systems

All solutions follow the principle: One worker – One padlock – One key, ensuring full control over energy isolation.

Need Support with Developing a LOTO Procedure?

A clear and well-structured Lockout-Tagout procedure is essential for safe maintenance. Our team can assist with drafting, reviewing, or optimizing LOTO or LOTOTO procedures, and can help you select the right lockout devices for your equipment.